Computer car wash machines are widely used, convenient for washing cars, clean and hygienic, and are deeply loved by users. Next, let's learn the operating principle and process of JH-903S computer car washing machine:

One; Under the status of tapping the start button

1. Light spot 1 induction; Optoelectronic 1 disconnected

(1) Conveyor action maintenance; (1) The conveyor will stop after a delay of about 10 seconds

(2) High pressure water spray maintenance; (2) High pressure water spray with a delay of about 5 seconds to stop

(3) Keep the front small brush closed (3) The front brush has a delay of about 15 seconds and the closing action stops;

(4) Front small brush rotation maintenance; (4) The front brush has a delay of about 15 seconds and the action stops

2. Optoelectronic 2 Induction; Optoelectronic 2 disconnected

(1) Conveyor action maintenance; (1) The conveyor will stop after a delay of about 10 seconds

(2) The spraying action is maintained, with a delay of about 20 seconds before stopping; (2) The top brush has a delay of about 5 seconds to maintain the action;

(3) Maintain the top brush descent action and stop when the top brush descends to the designated position; Raise to the top and brush up to position 1, stop 2

(4) Rear brush closing action maintained; (3) After a delay of about 5 seconds, the closing action stops,

Maintain the movement, divide to left/right, and stop in place

4. Optoelectronic 3 Induction; Optoelectronic 3 disconnected

(1) Conveyor action maintenance; (1) The conveyor will stop after a delay of about 10 seconds

(2) Top brush rotation action maintained; (2) Top brush delay of about 5 seconds to stop running

(3) The starting action of water pump 2 is maintained; (3) The top brush has a delay of about 5 seconds. The descent stops and the ascent stops

(4) Maintain the top brush descent action and stop when the top brush descends to the designated position; Maintain until reaching the top, brush up to the designated position, and stop

(5) Maintain the back small brush rotation action; (4) Pump 2 will stop after a delay of about 5 seconds

(6) Maintain the closing action of the rear small brush; (5) The rear brush has a delay of about 10 seconds and stops running

(7) Rear brush rotation action maintained; (6) After a delay of about 10 seconds, the closing action stops

(8) Front side brush rotation action maintained; (7) Front brush stops rotating

(9) Front brush delay of about 8 seconds, then the closing action is maintained; (8) Front brush closing action stopped (in minutes)

(10) Rear brush closing action maintained;

5: Optoelectronic 4 Induction; Photoelectric 4 disconnected

(1) Conveyor action maintenance; (1) The conveyor will stop after a delay of about 10 seconds

(2) Rear brush closing action maintained; (2) Rear brush closing action stops, separate action protection

(3) Rear brush rotation action maintained; Hold on, divide to left/right, stop in place

(4) The wax spraying action is maintained, with a delay of about 15 seconds before stopping; (3) Rear brush stops rotating

(5) Maintain the lowering action of the wind blade and stop when it reaches the designated position;

(6) Delay of about 5 seconds for fan 1 to maintain action;

(7) Delay of about 8 seconds for fan 2 to maintain action;

6: Optoelectronic 5 Induction; Optoelectronic 5 disconnected

Conveyor action maintenance; The conveyor will stop after a delay of about 10 seconds

Maintain the lowering action of the wind blade and stop when it reaches the designated position; Maintain the upward movement of the air vent and stop when it reaches the designated position;

Fan 1 maintains operation; Fan 1 stops running;

Fan 2 maintains action; Delay for 5 seconds, fan 2 stops running

6: Front left and right brush swing angle sensing;

Conveyor stopped

7: Top brush maintains sensing;

Top brush without lifting or lowering action;

8: Top brush up 1, 2 either induction

The top brush rises and stops at positions 1 and 2. If the top brush rises for 1 second, the conveyor will stop;

9: Top brush rises to position 1 and 2 simultaneously sensing

The upward movement of the top brush stops

11: Top brush lowering in place sensing

Top brush descent action stops

12: Rear left and right brush in place sensing

Rear left and right flashing actions stop

13: Rear left and right brushes maintain sensing

Rear left and right brushes have no opening or closing action

14: Rear left and right brush sensing

Rear left and right split motion

15: Rear left and right brush limit sensing

The left and right brushing actions on the rear side are maintained, and the conveyor stops

16: Photoelectric induction on the wind blade

The wind blade rises. If the photoelectric sensing time on the wind blade exceeds 1 second, the conveyor will stop.

17: Wind knife photoelectric induction

The wind knife has no lifting action

19: Wind knife rises to position 1 and 2 simultaneously sensing

The upward movement of the wind blade stops

20: Wind knife lowering in place induction

Stop the action of lowering the wind knife to its full position

21: Wind safety disconnection

Wind knife rises, conveyor stops

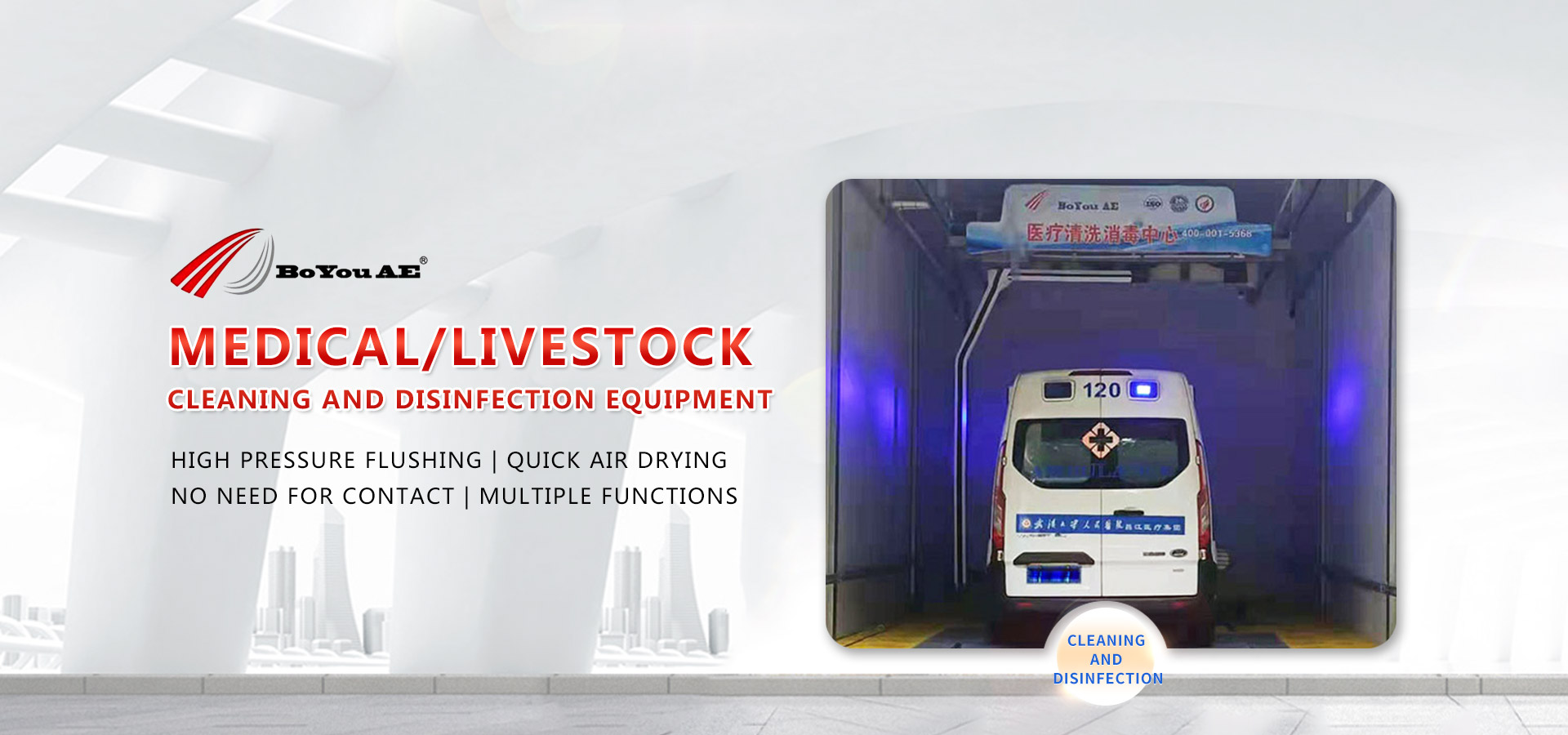

CLASSIFICATION

Product Center

Boyou unmanned car washing machine

Boyou all stainless steel precision care all-around car washing machine

Boyou Precision and Comprehensive Car Washing Machine

Boyou Precision Care and Rapid Car Washing Machine

Boyou Economic Comprehensive Car Washing Machine

Boyou Simple Wash Universal Car Washing Machine

Boyou Simple and Rapid Car Washing Machine

Boyou Puhui Universal Car Washing Machine

Boyou whirlwind all-around car washing machine

Boyou Cyclone Standard Car Washing Machine

Contact Us

Contact Us

National Consultation Hotline:

400-001-5368

Address: 500 meters east of the intersection of East Outer Ring Road and South Outer Ring Road in Zhucheng City, Weifang City, Shandong Province

Free service hotline: 400-001-5368

Phone: 0536-6160999

Manager Geng 18366537188 Email: boyouzidonghua@163.com

扫一扫,查看手机站

扫一扫,查看手机站