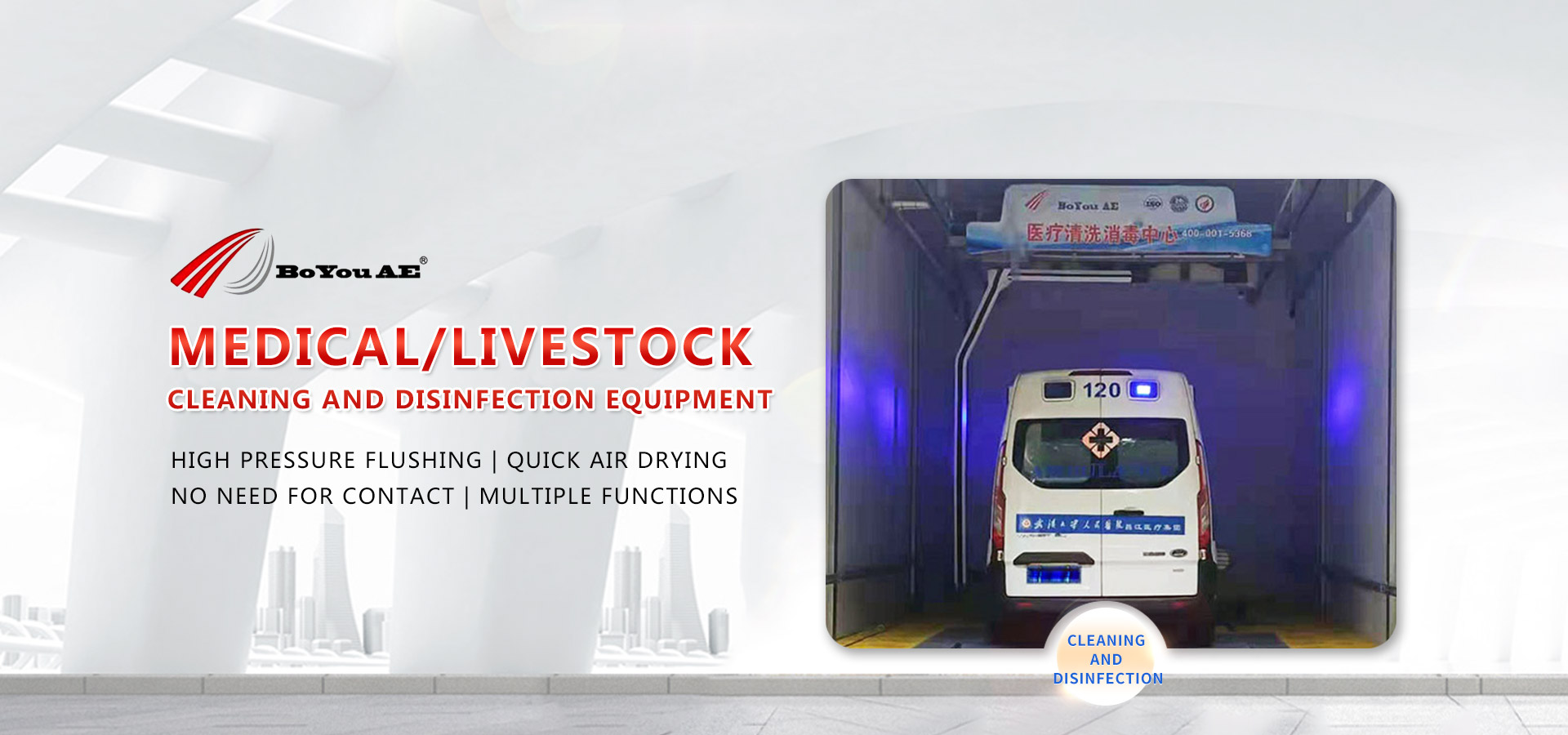

The reciprocating car washing machine is an important type of computerized car washing machine, widely used, highly automated, and deeply loved by consumers. Next, let's introduce the control system of the reciprocating car washing machine:

Control system of reciprocating car washing machine

Information and pictures of reciprocating car washing machine

The control system of reciprocating car washing machine is mainly divided into two categories, one is PLC technology, and the other is microcontroller technology. A misconception that needs to be corrected is that microcontrollers are CPUs while PLCs do not have CPUs. This statement is incorrect. PLC has its own CPU module. PLC relies on current sensing technology, combined with photoelectric sensing switches, to convert the pressure of the brush into electrical signals and transmit them to the CPU to sense the shape of the car body. The microcontroller technology also relies on photoelectric sensors to convert the recognized obstacle information into electrical signals and transmit them to the CPU. The advantages of PLC control system are easy maintenance, fast early development speed, strong anti-interference ability, but the disadvantages are more expensive and take up more space than microcontrollers; The advantages of microcontrollers are small space occupation and low price, but the disadvantages are long development cycle and poor anti-interference ability. All car washing machines in the world use PLC or microcontroller control systems.

Brush for reciprocating car washing machine

Many people say that reciprocating car wash machines damage the car paint. In fact, when a car is in motion and rubs against the air, a lot of dust will adhere to the surface of the car paint. Over time, a film will form, which will cause continuous damage to the car paint. High pressure water cannot wash off this film. A car washing machine with brushes can evenly remove the film, and the brushes are made of high composite materials, which will not cause damage to the car paint.

扫一扫,查看手机站

扫一扫,查看手机站